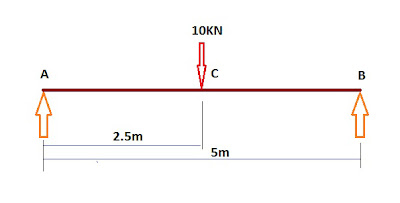

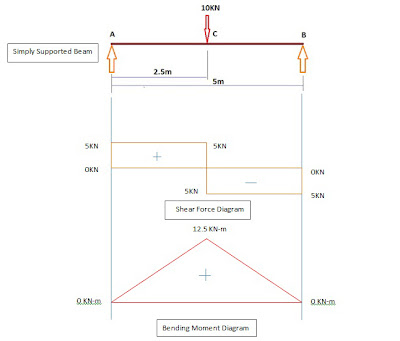

Here I will discuss about step by step Support Reaction Calculation Procedure. Say, there is a Simply Supported Beam with a Span Length Of L and Having a Point Load W at the Mid Span of the Beam. There are two supports A & B. The Reaction of Support A is RA and the Reaction of Support B is RB.

Now, The whole lode is to be carried by the two supports, as the beam is symmetrical and carrying the point load at the mid span it is thus obvious the total load will be equally shared between two supports. So the The Support A will take Half of the Load ( i.e. W/2) and the Support B will also carry Half of the Load ( i.e. W/2). To make the Beam to stay in Equilibrium The Total Load The Beam is Carrying must be equal to The Total Reaction The Supports are Giving.Thus,

RA + RB must be equal to W or RA + RB – W = 0. That means Sum of the Vertical Forces must be Equal to Zero, This the First Condition Of Equilibrium.

Now Calculating the Moments, here the Third Condition of Equilibrium that algebraic Sum of the all Moments about a section must be equal to Zero.

Taking Moment About B. Sign Conventions are, From Left to Right Clockwise Moment is taken as Positive and Anti-Clockwise Moment is taken as Negative.

Now first Observe the Loads and Reactions. There is only a single load in the mid span. That means The Distance of the Point Load and the Support B is Half of the Span i.e. L/2. And there are Two Reactions, RA and RB at two supports. Now Starting from the Support A and going towards support B we find 3 Forces one after another in the following Order, RA, W and RB. Now Calculating the Moment about B :-

+(RA*L) -(W*(L/2)) +(RB*0)= 0

Now as the Distance between the Point B and the Line of Action of the force RB is 0, the moment generated due to the force RB about the Point B is is equal to Zero. Thus the equation becomes,

+(RA*L) -(W*(L/2)) = 0 or +(RA*L) = (W*(L/2)) or RA = (W*(L/2))/L.

Thus, we can find the RA, and as the whole load is carried by the the two supports, the value of RB will be,

RB = Total Load – RA or RB = W – RA , or just simply put the value of RA in the first equation,

RA + RB – W = 0.

The above Procedure is a general procedure to Calculate the Reactions for any type of point Loading on a Simply supported Beam.

In the above case the reaction can be known easily as the Beam is carrying the point load at the mid span. The load sharing will be two equal half of the load on two supports, thus the Reactions will be equal to Half of the load at each of the supports.

Follow Techno Genome at :-