Civil Engineering is vast field from Culverts to Dam , Buildings To Steel Bridges, so as so the Civil Engineering Materials, It includes Steel, Concrete, Timber, Aluminium, Glass etc. Steel Design is much easier in most of the cases than RCC Design in Structural Engineering. Civil Engineering Broadly has three main phase namely Planning – consisting of Drawing, Estimating etc. Structural Engineering Design consisting of Analysis of Structures and Design Of Structures and last of all Execution which means erecting the actual work according to the Planning and Designing. Structural Engineering has always been a field of respect amongst all the Civil Engineers. Today I will discuss about a part of Structural Engineering which will be dedicated toward the Design of Steel Beam specifically Steel I Beam. After reading this article you will be able to design a steel beam by your own without any problem. To make the explanation easy for understanding I will elaborate a simple yet considerably good problem which will cover all your needs as far as the Civil Engineering and Structural Design is concerned. I know now a days all the Structural Engineering Analysis and Design is being done by Computer Software like STAAD Pro, Ansys and all that, but without having the knowledge of manual Design of civil and structural engineering all those are useless because you will be not able to understand the Design Data and the outcome from the software. But before going to start You need to understand few things which I should tell you first or at the later stage you may find some problem.

What is a Structural Engineer and Job Profile :-

Civil Engineering as you already know is a vast field with full of opportunities, there are every aspect of civilization which is either directly or indirectly elated and proportional with the growth of the civil engineering field itself. Civil Engineering mainly deals with the few categories of engineers who take cares of different things, like Structural Engineer who deals with the all civil engineering structural design and analysis works for the safety and stability of the structure. Another important filed very close to Structural Engineering is Geotechnical Engineering which deals with the all about soil and its data collections tests bearing capacity determinations etc. And there is also Construction Engineers who do the actual construction on the field. In civil engineering structural engineer generally performs the structural design of Beams columns foundations slabs and other structural components, and also does the analysis jobs of an existing structure for determining its ability to carry loafs that it has been designed for. These Structural Engineer are well recognized among all the other fields of civil engineering. Structural Engineer and there jobs are mainly outsourced to a third party structural engineering firms in most cases.

As a Civil Construction material steel was vastly used in early days for building works and in cases where the loads are heavy but now a days most of the buildings are made of RCC however Steel is used in the places like Steel Bridge Design, Railways, Docks , Over bridges and etc. places where the loads are very heavy because the Bearing and Shearing capabilities of Steel is more than Concrete. And many a buildings in places like United Kingdom, United States, Australia and many other modern countries Slab Beam and Column Design are still being done with Steel as a Civil Construction material. Steel which are used in structural design as a construction material are used in the form of Rolled Steel Sections of different shapes like I Sections, Channels, Tubes, and also in built up sections. For Design of Steel beam mainly I sections are used. Now remember that great equation of the Theory of Bending which is (M/I) = (f/y) = (E/R) , I know you can steel recall this don’t you?. Okay let us just recap it in an easy way, in this equation the denotations are as follows :-

M = Bending Moment Acting on the Beam due to loads

I = Moment of Inertia of the Beam section

f = Bending Stress in the Steel Beam

y = Distance between the any fibre of section and the Neutral Axis [For getting maximum Bending Stress the value of y must be maximum as the Bending Stress is directly proportional to the distance between fibre at a point and the Neutral Axis, hence we need to consider extreme fibre which gives maximum value of ‘y’, this equals to h/2 where h is the depth of section, as the Neutral Axis of symmetrical sections like I-Section will fall at its C.G.]

E = Modulus of Elasticity of the Beam section

R = Radius of Curvature of the Shape of Bending of the Beam

But we won’t be needing all these, we just need the (M/I) =(f/y) for the design of steel beam.

Now we can rewrite the equation (M/I) =(f/y) as (M/f) = (i/y) can we? Yes we surely can by cross multiplication. Here the term obtained (i/y) is known as Section Modulus and this is a very important factor because upon it the strength of any section depends. Actually When the Maximum distance between Neutral Axis and the fibre is considered, that is the distance between the Neutral Axis and the extreme fibre, meaning the maximum value of ‘y’, This term (i/ymax) or Section Modulus is denoted with ‘Z’ , therefore Z=(i/ymax) . I hope up to this level you have understood, and these things you have already studied in structural analysis isn’t it? Yes you have for sure. So basically in a Structural Steel Design of Beam we will design the beam for flexur, that is for Maximum Bending Moment and then chose a suitable Beam section from the list of available sections which varies from country to country and this list can obtained from bureau of standards of your country. And after choosing that section then we will check for other factors like Shear Stress, Deflection and look if that section can stand safely. That’s all isn’t it simple? Okay now lets get started, I will discuss How to Design a Steel Beam in Step By Step that You cannot escape without Understanding.

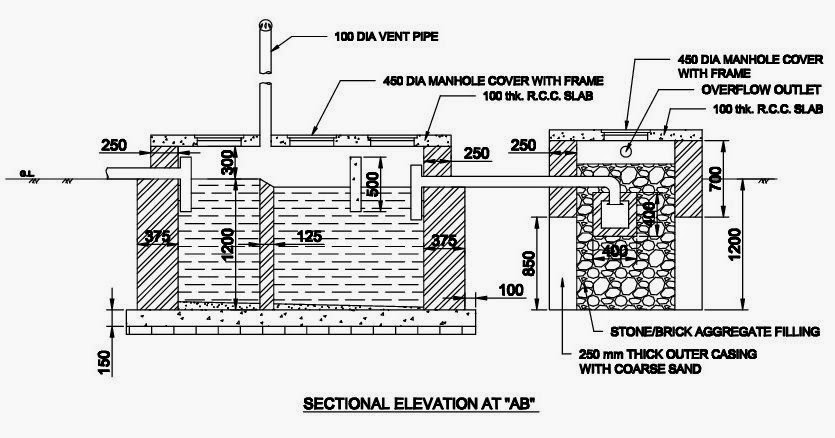

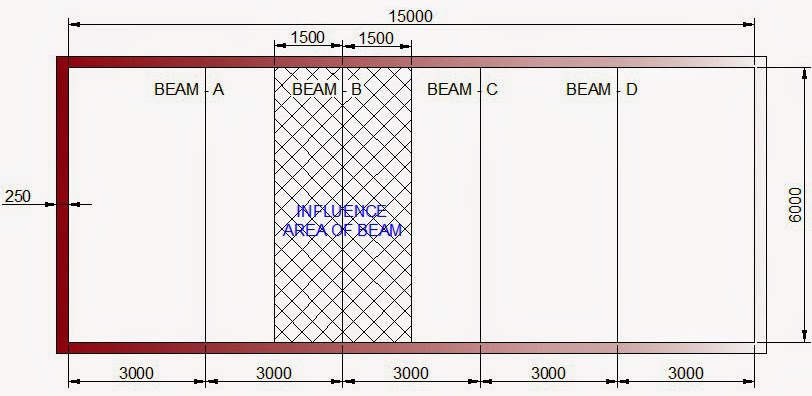

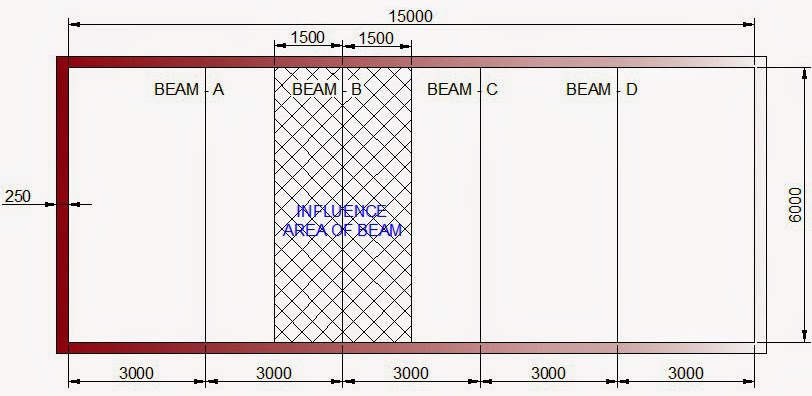

Let us consider a problem for explanation, suppose there is a hall room measuring 15m X 6m inside and the walls are 250mm thick. And it is given or you have thought to provide beams at a centre to centre distance of 3m apart. The beams are supporting a R.C.C. roof slab of 150mm thick with finishing on it, the flanges being restrained on slab. The Hall is a commercial type building. So let us design these beams.

Step 1 – Preparing a Neat Sketch from the Problem For Steel Beam Design :-

This is important in all types of Civil Engineering Structural Design Problem. As You know Drawing is the Language of Engineers and Line is the Language of Drawing, so prepare a neat drawing after reading the problem and give all the dimensions possible in the drawing. A Drawing is a must and it must be 100% correct as all the designing will be dependent upon this drawing. So prepare the drawing with caution. Here I’ve prepared one, now study it thoroughly, What Data you are getting? Yes the inside dimensions of the room that is 15m X 6m, This thickness of the wall which will act as the bearing of the beam are 250mm thick, and the Centre to Centre distance between the beam that is 3m.

|

| STEEL BEAM PLAN |

Step 2 – Calculation of the Influence Area of the Structural Steel Beam :-

The Influence Area of a Beam means the area of which the loads are acting that beam, or simply you can say that the beams have to be designed for the loads on that area that is the influence are. Here in this particular problem we see that all the beams are in a similar situation, that means they are within a same room and same direction, they are supporting the same roof with same finishing, and these beams are spaced at a same distance, that means the condition of all these beams are identical to each other, so we will do structural design for any one of the beams and that design will be fit for other beams. If the conditions were not identical then we have to design each of them individually for economy or we have to design the beam which is having the greatest load on it. Let us consider the Beam B for Design

Here all beams are 3m apart C/C distance from each other, hence a single beam B is having Beam A on the left at 3m distance apart and Beam C on the right side is also 3m apart, so the Beam B is supporting half of the load of the area between Beam B and Beam A on the left side and on the right side the Beam B is supporting half of the load of the area between Beam B and Beam C. Hence it means on the left side supporting a strip of (3/2) = 1.5m width and on the right side again supporting a strip of (3/2) = 1.5m width. So the influence area becomes a strip of width 1.5m + 1.5 m = 3m and its length being from centre to centre of the bearing at the each end of the Beam that is the Effective Length of the Beam.

|

| STEEL BEAM I – SECTION |

Step 3 – Calculation Of Loads acting on the Steel Beam :-

Now we have to calculate the loads acting on that influence area as calculated above as Civil Engineering Structural Design will be based on these Loads. These loads can be broadly classified as Dead Loads and Live Loads. Dad loads means the loads coming from all unmovable Objects like Slab, Beam itself, Flooring etc. and Live Loads Means the load coming due to the movable objects such as we humans, furniture and other movable loads. Generally Dead Loads are calculated and Live Loads are specified according to the Type of the structure, varying in intensities with different types. Like for residential building generally it is 2 KN/ m2 and for Commercial Building it is 4 KN/m2. The Dead Loads which are to be calculated are as follows:-

Dead Loads – 1) Self weight of beam(Assumed 1KN per m)

2) Load of slab supported @25 KN /m3 for R.C.C.

3) Load of floor finishing (generally 0.5KN/m2)

4) Load of Brickwork if any @19.2 KN/m3

All the loads are to be calculated on per m run basis so that it becomes a U.D.L. The total load acting on the beam will be the sum of the Dead Loads and Live Loads

Therefore, Total Load per metre run, w = Dead Loads + Live Loads

Here in this case the load calculation will be as follows :

A) Dead Loads –

I. Due to the self weight of the beam – 1 KN/m

II. Due to the 150mm thick slab = (1 x 3 x 0.15) x 25 = 11.25 KN/m that is [Length x Breadth x Thickness] x Density

III. Due to Floor Finishing @ 0.5 KN/m2 = (1 x 3) x 0.5 = 1.5 KN/m that is [Length x Breadth] x Load Intensity

B)Live Load – @ 4 KN/m2 = (1 x 3) x 4 = 12 KN/m [Length x Breadth] x Load Intensity

Therefore, Total Load per metre run, w = (1 + 11.25 + 1.5) +12 = 13.75 + 12 = 25.75 KN/m

Step 4 – Calculation of Effective Length Steel Beam :-

It is taken as the length between the centre of bearings of the beam at each end.

Therefore in our case having a clear span of 6m and 250mm support at each end by means of wall we get,

Effective length, l = 6 + (0.25/2) + (0.25/2) = 6+0.125+0.125 = 6.25m

Step 5 – Calculation of Maximum Bending Moment On The Steel Beam :-

Here we will introduce the Structural Steel Beam Design Formulae for the first time. Now calculate the maximum bending moment acting on the beam by adopting suitable formula which are as follows :-

i) For point load at the mid span of the beam: – M = (w.l/4)

ii) For U.D.L. Throughout the span of the beam :- M= (w.l2/8)

iii) For Point load at any point of beam :- M = (w.a.b/l)

For any unusual loading you have to calculate the maximum bending moment and shear force by shear force bending moment diagram drawing procedure.

Here in this case as we are having a U.D.L. of 25.75 KN/m throughout the span hence we will use the second formula that is M = (w.l2/8)

Therefore, in our problem we get,

Maximum Bending Moment, M = (w.l2/8) = ((25.75 x 6.252)/8) = 125.73 KN-m

= 125.73 x1000 x 1000 N-mm = 125730000 N-mm

Step 6 – Calculation of Section Modulus Required For Steel I Beam :-

Here we will use another Civil and Structural Engineering Design Formula for steel beam design. Here we will determine the Section Modulus required in order to resist the Maximum Bending Moment acting on the beam. At the star of this article we had found that (M/I) = (f/y) or (M/f) = (i/y) again Z=(i/ymax) therefore we can rewrite it as Z=(M/f). The value of ‘f’ depends upon the grade of steel and factor of safety. Considering Fe250 Grade of steel, and according to code of practice of the different country the factor safety will vary for obtaining the permissible stress (f) from the Yield Strength of Steel. Here I will follow the IS 800 Code and according to it Maximum Permissible Stress = 0.66 X Yield Strength. But in case of I beam and channel with equal flanges the permissible bending compressive stress shall be calculated from the table given in the code by knowing the value of ((D/T)/(l/ryy)) where,

D = Overall depth of the beam

T = Mean thickness of gthe compression flange, which equals to the area of horizontal portion of flange divided by width

l = Effective length of compression flange

ryy = Radius of gyration of section about its axis of minimum strength (y-y axis)

However the value of permissible compressive stress shall never exceed 0.66fy, where fy = Yield Strength of Steel. Here for easy understanding considering that the permissible compressive stress has got the same value that of 0.66fy.

in case of Fe250 the Yield Strength is 250 N/mm2, Hence Maximum Permissible Stress, f = 0.66 x 250 = 165 N/mm2.

Thus returning to our problem we get that,

Zrequired = (M/f) = (125730000/165) = 762000 mm3 [Unit Derivation, Z = (i/ymax) = (mm4/mm) = mm3]

For selecting a suitable section from the steel table that is the chart of Rolled Steel Section we have to get the value in terms of cm3, Hence 762000 mm3 = (762000/(10x10x10)) = 762 cm3

Step 7 – Steel I Beam Selection of Suitable Section from Steel Table :-

Now we have to use the steel table which has the standard Rolled Steel Section List and their properties written on. These Tables are country specific and will vary from United Kingdom to United States to Australia to India. So you need to use your country specific steel table. We have to choose a section, preferably a I Section from the Steel Table, which will have a Section Modulus (use section modulus about –x-x axis) or ‘Z’ equal to or greater than what is found to be required (Zrequired), and also have to note all necessary properties of that Steel Section. In our case I will use SP-6 Steel Table, and I have found the following section to be suitable in case of our Civil Engineering Design Problem:-

Let us Try ISMB 350 @52.4 kg/m Having the following properties,

Sectional Area, a =66.71 cm2

Depth of Section, h = 350mm

Thickness of Web, tw = 8.1mm

Moment of Inertia, Ixx = 13630.3cm4

Section Modulus, Zxx = 778.9 cm3

Step 8 – Check For Shear Of Steel Beam :-

As of now we have made a design based on flexural strength that is based on Maximum Bending Moment, and selected such a section which will be safe in Bending. Now we have to check if that section will be safe in shear or not. For this we have to calculate the Maximum Shear Force acting on the beam, as for U.D.L. this can be calculated by using the Structural Engineering Analysis Formula V=(w.l/2) , where,

V = Maximum Shear Force

w = Load per metre run

l = Effective Length of the Beam

Then by this shear force we have to calculate the average shear stress on the beam due to the Maximum Shear Force, by using the formula Tva = (V/h.tw), After getting this Average Shear Stress we have to calculate the permissible Shear Stress which depends upon the grade of steel and also upon the factor of safety which is varying according to Code of Practice of different country, according to IS 800 Permissible Shear Stress = 0.4 x Yield Strength of Steel, Hence for Fe250 Grade Steel we get, Permissible Shear Stress, Tvm = 0.4 x 250 = 100 N/mm2. Now if the permissible stress is greater than or equal to that of the Average Shear Stress on Beam then the Section is Safe In Shear, or else it is unsafe therefore, we have to select the next higher section in terms of Section Modulus and area of Web (h.tw) and give trial for shear check, until it becomes safe.

In Our case of problem it will be as follows :-

Maximum Shear Force, V = (w.l/2) = ((25.75 x 6.25)/2) = 80.45 KN = 80450 N

Average Shear Stress in Beam, Tva = (V/h.tw) = (80450/(350 x 8.1)) = 28.38 N/mm2 < 100 N/mm2

Hence the section is Safe In Shear.

|

| STEEL COLUMN BEAM CONNECTION |

Step 9 – Check for Deflection Of Steel Beam :-

We are almost done in the Design of Steel Beam, this the last check we have to perform, the rule is same, if the section satisfies the check then it is safe, or otherwise we have to check with another section having more depth (h). For this check we have to calculate the Actual Deflection on the beam by using the Structural Analysis Formula in case of U.D.L. the formula is :-

Del(Symbolic) = (5/384) x (W.l3/E.I)

Where,

Del = Deflection in cm

W = Total Load = w.l in N

E = Modulus of Elasticity, For Steel E = 2 x 105 N/cm2

l = Effective Length in cm [ Small L]

I = Moment of Inertia in cm4 [Notation = Capital Eye]

And Permissible Deflection = l/300

Here, In the case of our problem the calculations will be as follows :-

W = Total Load = w.l = 25.75 x 6.25 = 160.94 KN = 160940 N

E = 2 x 107 N/cm2

l = 6.25 m = 625 cm

I = 13630.3 cm4

Actual Deflection, Del = (5/384) x (W.l3/E.I) = (5/384) X ((160940 X 6253)/((2×107) X 13630.3)) = 1.877 cm

Permissible Deflection = l/300 = 625/300 = 2.083 cm > Actual Deflection, Hence Safe.

Therefore The Section selected by us is Safe in All Respects.

Therefore Let Us Provide ISMB 350 @ 52.4 kg/m

Apart from these checks there are also other checks like, Check for Vertical Buckling [Important for Point Loads], Check for Direct Compression in Web, Check for Diagonal Buckling.This check procedure have not been included in this article now, but will be Updated Soon.

For making this Article Universal I’ve used only Common Terms and Denotations which are well known in all of the Countries Like United Kingdom, United States, Australia, India and other places, as the Denotations may vary Code to Code of Different Countries.

Now the Structural Design of Steel Beam has successfully completed in all respect. I hope You understood all along with ease, I’ve made it as much as easy as possible. Do Share the Link of this Article On Your Network Of People of All Fellow Civil Engineers and Your Social Network as a Token for Appreciation of this Article if this Article Helped You in Understanding.Keep Visiting MyCivil- Civil Engineering Redefined for more Articles at www.mycivil.engineer. Please do comment on this post, as your comments are very important to me so that I can understand if you are having any problem, and also it will be helpful for others who will visit this Blog. Join This Blog for Regular Updates and also you can now follow us in the Facebook, Twitter and also on LinkedIN.

If you like this Article then I am sure you will like the following well researched articles too, come on check them out also